Simulation of the Mechanical Stability of Inkjet-Printed Hierarchical Microsieves

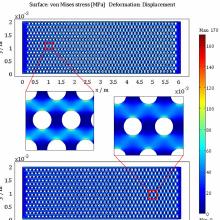

Porous membranes with pore sizes in the micrometer scale are required in many micro systems dedicated to biological and chemical applications. If their thickness is in the same dimension like the pore diameter they are called microsieves. On the one hand, a thin membrane guarantees a small flow resistance but on the other hand the mechanical strength is reduced. We developed a process which allows the individual positioning of each single pore in a polymer microsieve by inkjet printing. Though, a hierarchical arrangement of the pores in the microsieve is possible. Our goal was finding a compromise between high mechanical strength and high permeability. We simulated the mechanical strength of various hierarchical arrangements of the pores by using COMSOL Multiphysics. We implemented a 3D model where every pore is defined in its characteristic shape. The mechanical strength was tested by applying a tensile stress onto the membrane. Finally, we investigated the correlation of the simulated results to experimentally conducted tensile tests.

Download

- hackert_paper.pdf - 0.38MB