The epitaxial growth of SiC by PVT method

Application ID: 107351

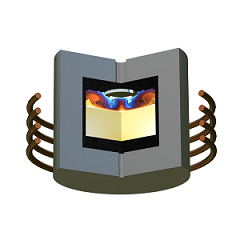

Silicon Carbide (SiC) Epitaxial Furnace is a specialized equipment for the production and preparation of SiC Epitaxial Wafers. This model demonstrates the process of preparing SiC Epitaxial Wafer based on the Physical Vapor Transport (PVT) method in a furnace. This involves heating the SiC powder via an induction coil. As the powder reaches a specific temperature, it begins to sublimate. As the vaporized SiC rises up to the top of the furnace, the temperature goes down, leading to the deposition of the SiC on the wafer surface, which is placed at the top of the furnace, with a layer of crystal seeds on the surface. This process involves complicated multiphysics phenomena, including electromagnetic heating, natural convection and surface-to-surface radiation in the furnace, mass transfer, sublimation and deposition of the SiC vapor.

In the model, the deposition and sublimation rate are given by the imported experimental data. A BODE interface is used to calculate the thickness of the epitaxial layer. This model can be further extended to include the effects of the surface reaction on the wafer, the mass transfer of the SiC vapor in the powder, the PID temperature control of the coils.

This model example illustrates applications of this type that would nominally be built using the following products:

however, additional products may be required to completely define and model it. Furthermore, this example may also be defined and modeled using components from the following product combinations:

The combination of COMSOL® products required to model your application depends on several factors and may include boundary conditions, material properties, physics interfaces, and part libraries. Particular functionality may be common to several products. To determine the right combination of products for your modeling needs, review the Specification Chart and make use of a free evaluation license. The COMSOL Sales and Support teams are available for answering any questions you may have regarding this.