We’ve noticed that a lot of our customers use spreadsheets, such as Excel®, as part of the modeling process. They use them for storing material property and other data, such as from experiments or other information about workflow associated with their engineering project, and then import this data into COMSOL Multiphysics®. Spreadsheets are also the forum for taking in results from COMSOL software and using this to compare, optimize and verify these material properties. Let’s delve deeper into how spreadsheets are used in engineering — do you recognize your own role in this process, perhaps?

Using Spreadsheets to Find the Answer

Take this structural mechanics example of a rubber part. What happens when you pull on it; how much does it stretch, when does it weaken, when does it break…? What would the physical model for stretching the rubber part be? When utilizing spreadsheets to figure out the answer to this, one would start by running experiments to see how the part reacts to different scenarios. These are then stored in the spreadsheet where they can be analyzed, and maybe parameters like material properties be extracted, often as an averaged value.

But, what is the optimal design of this component? Up until now, we’ve been working within the Excel environment, but in order to find out what the best design would be, each scenario needs to be solved for and compared to the experiment.

Cue: The Simulations Engineer

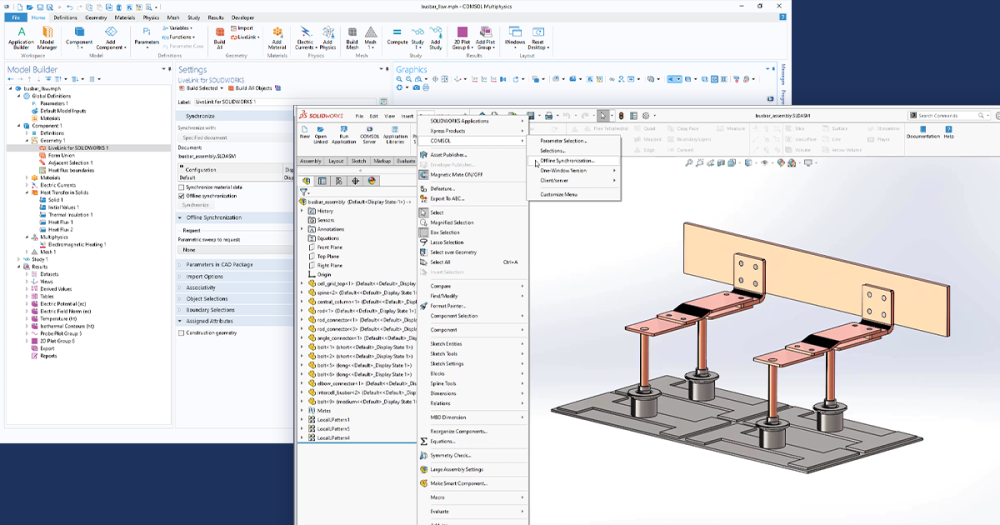

He or she is the go-to person for building a useful model. The engineer receives the Excel file with the material property data from his colleague and imports these into COMSOL Multiphysics. Interpolation functions in the software allow for better and more localized determination of the material property, and these are used to model the different scenarios.

The results from the simulations can then be given in a table, which can be further exported to Excel, and the engineer can now send the file back to his colleague who set up the different scenarios. The COMSOL software results are then compared to the original scenarios in Excel to see how these values compare to the values for the variables in the initial studies.

As far as we’ve seen, spreadsheets are mostly used for mechanical, magnetic, and chemical applications. Experiment is often required to provide the material data for materials, as well chemical reaction kinetics. But, if you work in another area that uses Excel as part of the simulation process, tell us about it in the comments section below!

Spreadsheets, a Widely Used Application

One of the great aspects of incorporating spreadsheets into the world of multiphysics modeling is that someone within the organization can enter data into Excel (a widely used application) and then use that in a simulation. Conversely, that simulations engineer can later export the results data into a spreadsheet format and send that back to the experimentalist — who can then use the results from the simulation in a familiar environment. The downside is, of course, that because these scenarios are run manually, and the processes are separated across different employees, it can take weeks or months to run through the project workflow. Wouldn’t it be great if at least parts of this process could be automated? Food for thought.

Comments (1)

Ivar Kjelberg

September 19, 2012Spreadsheets are handy, but can be tricky: for several years copying scientific notation data from EXCEL to WORD made all sci notation number differ by an order of magnitude, as the convention in EXCEL was 1-9Enn and WORD 0.1-0.9Enn. Luckily this has been corrected in later releases 😉 So even with common tools, careful validation is required.

If I remember right, one of the recommandations of the NASA Columbia accident reports said explicitely: do not use spreadsheets alone for serious scientific and engineering calculations.